Secrets to a High-Quality Driveway: Tips from Concrete Contractors in El Paso, TX

Every contractor has their own techniques for installing a concrete driveway but that doesn’t mean that all of them are effective or practical. There is an established standard in crafting a concrete driveway but we all know that the standards are not always the best especially in specific cases depending on your situation. This is the part where expertise and experience come into play. Concrete contractors in El Paso, TX have unveiled their secrets to mastering their craft, particularly in creating

high-quality concrete driveways.

Here are some tips from the experts that you should check out:

The Foundation of Success: Planning and Designs

The planning and designing process is the cornerstone to installing the

perfect concrete driveway for you. It’s not a secret but some people neglect its importance. Not all driveways should have a similar process to follow. It depends on your preference and your area requirements.

Driveway Width:

It should be at least 10 to 12 feet wide for single-car driveways and 20 to 24 feet for double-car concrete driveway.

Slope and Drainage:

El Paso concrete contractors recommend a 1-2% slope to guide water away from the house and driveway.

Concrete Thickness:

This depends on how much load-bearing weight your concrete driveway should carry. 4 inches is usually sufficient, but areas with heavier traffic or larger vehicles might require 6 inches or more.

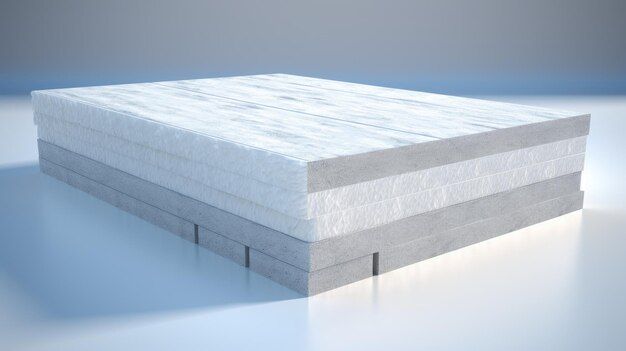

The Backbone of Durability: Quality Materials

For obvious reasons, materials significantly affect the quality of every work. In concrete driveways, the right concrete mix, reinforcement, and aggregates can determine the strength and durability of your driveway.

High-Grade Concrete Mix:

The balance of every material in the concrete mix such as cement, sand, gravel, and water matters. A mix with a comprehensive strength of 4,000 psi is typically recommended.

Reinforcement:

El Paso concrete contractors often use #3 or #4 rebar placed at 18-inch intervals. This adds structural integrity and prevents cracks and shifting.

The Hidden Key for Longevity: Control Subgrade Preparation

This is technically hidden since it’s underneath the concrete, which is the primary component of a driveway’s durability. If the subgrade is not prepared properly, there are more chances that your driveway will become prone to settling, cracking, and premature wear.

Here’s what the concrete contractor in El Paso recommends:

Soil Testing and Compaction:

Use a granular base such as crushed stone or gravel to minimize expansion and contraction underneath.

Grading:

Grade the subgrade so that the water will not seep underneath the concrete, avoiding frost heave or erosion.

A Crucial Step Often Overlooked: Curing

Curing gives concrete a boost to achieve its full strength, which makes it so important.

But keep in mind these:

Keep It Moist:

It is important to keep the concrete moist during the curing process. Concrete contractors in El Paso, TX utilize techniques such as wet coverings or applying a curing compound to retain moisture.

Time Matters:

7 days is the typical curing duration, but 28 days is ideal for optimal results. While in this process, it is best to avoid heavy loads or too much use.

The Cherry on Top: Finishing Touches

The finishing process involves scaling up the driveway’s aesthetics with its maximum output of durability, which also impacts safety and longevity.

Here are the finishing tips from El Paso Concrete Contractors:

Texture Finishes:

There are a lot of designs you can choose from but for safety and to avoid slippery results, you can choose a broom finish.

Edge Work:

Edging is essential not only to add more elements but also to prevent chipping. This process kills two birds in one stone.

Sealant Application:

This acts like sunscreen for your concrete, blocking water, stains, and freeze-thaw cycles. The sealer should be reapplied every 2-3 years for best results.

The Final Secret to a Long-Lasting Concrete Driveway: Maintenance

Even the most durable concrete driveway in the world would deteriorate if not maintained properly.

Here are some points:

Regular Cleaning:

Sweep and wash away debris to prevent stains and surface damage. You can also use a mild pressure washer for a better cleaning result.

Seal Cracks Promptly:

This is very crucial as concrete damages such as cracks can become a serious problem if left untreated. You can use patches or sealants that are designed specifically for concrete driveways.

Avoid Harsh Chemicals:

Don’t use quick and easy but harsh cleaning methods such as de-icers and other harsh chemicals as they can damage the concrete surface of your driveway. Use natural materials such as sand for traction during icy conditions.

Conclusion

These tips are just the tip of the iceberg. The experience that El Paso concrete contractors obtained enabled them to perform uncommon steps but significantly effective based on tests and observations conducted—which sets them apart. Basic foundation in construction is good but paying attention to specific requirements for the highest possible result is even better—something El Paso concrete contractors specialize in. In fact, there is no secret in creating a well-crafted concrete driveway. All you have to do is select a great contractor. If you are looking for one, send us a message today.