EL PASO CONCRETE CONTRACTORS

CALL US NOW 915-529-4322

Different Types of Decorative Concrete

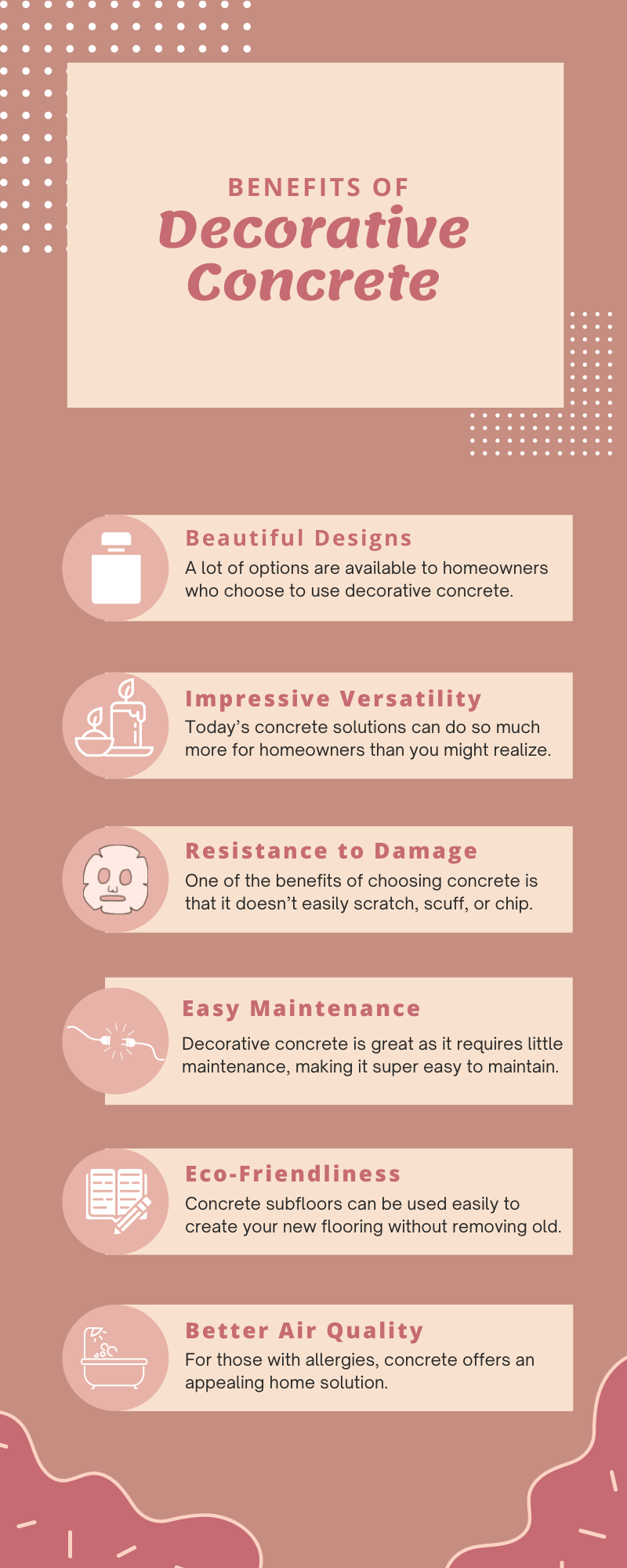

The days of simple grey concrete slabs being the only choice for flooring, driveways, sidewalks, and patios are long gone. There are now various alternatives for using concrete to give any house or business structure a decorative touch. Traditional concrete can now be stamped, stained, colored, polished, engraved, and even resurfaced after being placed. It's accessible as a countertop or a stunning interior floor with inlays and overlays.

Commercial and residential buildings are now adding unique designs to their concrete floors, worktops, entryways, patios, pool decks, and other property elements. Colored concrete, when properly done, can provide a decorative architectural look to practically any project.

What is Decorative Concrete?

Decorative concrete is simply ordinary concrete with the addition of distinctive colors, patterns, or finishes. Decorative concrete can also act as a security feature; for example, adding texture to concrete creates a non-slip finish ideal for use around pools or in areas frequented by youngsters and the elderly.

Many types and designs of ornamental concrete have come and gone over the years, so the key is to go with something conventional and strong that you will appreciate yourself for a long time.

Different Types of Decorative Concrete

There are numerous methods to use decorative concrete. One way is to add additional elements to the concrete mix before pouring. Alternatively, when typical concrete has hardened, an extra decorative layer can be applied on top. Here are the some popular types of decorative concrete:

- Stamped Concrete

- Stained Concrete

- Concrete Overlays

- Colored Concrete

- Concrete Dyes

- Polished Concrete

- Engraving Concrete

- Resurfacing Concrete

Stamped Concrete

Concrete builders can use special machines to imprint a variety of patterns into freshly poured concrete. These frequently imitate the appearance of brick or stone pavement at a fraction of the expense. Stamped concrete adds texture to practically any interior or exterior concrete pour. It can be used with concrete colors and a variety of impressions. Stamped concrete can be used with other textured concrete elements such as tile, wood, or stone by using designs and colors.

Stained Concrete

Staining concrete, which comes in a number of colors, can quickly turn the drab grey standard concrete tint into a range of color patterns. Highly innovative stained concrete applications can replicate natural items such as leather, wood, marble, and natural stone. It is the best method for improving the aesthetics of pathways, patios, driveways, concrete walls, pool decks, and other surfaces.

Concrete Overlays

Decorative concrete overlays can rapidly revive worn, damaged, or deteriorating concrete. This decorative feature can enhance the surface of the concrete both outdoors and interior while also offering a comprehensive look. Concrete overlays are a low-cost alternative to replacing old concrete. New technological developments improve the overlay's performance, enhancing aesthetic attributes and strong wear resistance.

Colored Concrete

Color concrete plans come in various colors and tints, including brilliant multicolored solutions and more rustic earth-toned colors and shades. The coloring elements can be mixed into the wet concrete mix or placed straight to the surface shortly before it hardens fully. Furthermore, colors can be placed on any completed concrete and will not react chemically like acidic stains.

Concrete Dyes

Concrete dyes have been used for years to help change the color of concrete, but new developments have made them more successful than in the past. Outdoors, alcohol-based colors are ineffective because they disappear quickly in the sun. The most recent concrete dyes are blended with the best methods to prevent fading in the sun, including a UV inhibiting ingredient. Nonetheless, when exposed to direct sunshine regularly, concrete colors fade by 5 to 8 percent annually.

Polished Concrete

Due to new breakthrough polishing equipment technology, concrete contractors can now add a high-gloss polished decorative accent to concrete floor surfaces. Adding a high-gloss finish to the concrete surface eliminates the need for additional coatings or waxes to keep the surface looking polished. Many homeowners and commercial properties, such as retail businesses, office buildings, and warehouses, opt for shiny concrete flooring as an alternative to linoleum, granite, tile, and marble. It adds a decorative shine that resembles the look of highly polished stone.

Engraving Concrete

Cutting patterns and grooves into the surface of existing concrete can be used to rebuild it. A portable CNC concrete engraving equipment can carve intricate designs such as logos or text.

Geometric patterns, straight or curved lines, and bespoke designs can be carved directly into the surface of the concrete to simulate the look of tile, flagstone, cobblestone, and many other typical surface patterns. This is typically conducted using tools such as an angle grinder fitted with diamond blades. However, it is more successfully accomplished with specialized tools for cutting patterns into concrete.

Resurfacing Concrete

For a damaged or discolored concrete surface, removing and replacing it is no longer the only option. The concrete can now be completely resurfaced, saving money while improving its beauty. Concrete can be transformed into a variety of attractive decorative designs using a variety of methods.

Conclusion

Decorative concrete is frequently used in both business and residential places. The decorative floors can be prefabricated based on the project. Decorative concrete will protect your floor from heavy loads, weather, mold, and dust. Aside from the numerous other advantages of decorative concrete flooring, you can install them in your house or business at a moderate cost. It is not expensive to install and is incredibly sturdy and resistant to the majority of problems.

Approved